Pond-Free 101 Chapter 8

Managing Pond-free Pump Costs

This might not be the best place to discuss this, but if you’re thinking of building a Pond-free water feature, your pump and plumbing choices will make a big difference in your operating costs, which can mount up fast. For example, the monthly cost to run a pump is your average electric cost per kilowatt/hr times the pump wattage times 720 hours per month divided by 1000. Running 24/7, at $0.10/kW/hr, a 1000 Watt pump will cost $72 per month to run. (Check out the College of Pumps for a full explanation of pumps, plumbing and costs.) These tips will help you keep your water feature as affordable as possible.

-

Use the lowest head pump that will get the job done. Let’s take a quick look at the work your pump has to do. It has to raise water to the height of the top of the falls, that’s the Vertical Head Height. It also has to force that water up to the falls through pipe and fittings that can be restrictive; that’s the Friction Head. The two components combined are the Total Dynamic Head, the total work the pump has to do to power any given water feature. Just like with cars, you want to match the motor to the work. If you’re just commuting to work every day at 30mph, you might not want to use a high performance muscle car that does 150 but gets 10mpg. On the other hand, if you need to go 150mph or move a ton of furniture or pull a heavy trailer, you’re going to need more muscle. The idea is to use (and pay for) only as much power as you need. The same goes for pumps. A low-head pump will cost far less to run than one capable of producing high head, so figuring out the Total Dynamic Head of your system so you know exactly what you need really pays off right from the beginning. One easy way to find the right flow at the right head for the lowest wattage is to use the Atlantic Water Gardens Let’s Talk Pumps Trifold. You put in the average width of the waterfall, the length of the stream if any and the desired visual effect you want to achieve and the worksheet will determine the appropriate pump capacity and tubing size, calculate your TDH and let you choose the right pump with the lowest wattage.

Use the lowest head pump that will get the job done. Let’s take a quick look at the work your pump has to do. It has to raise water to the height of the top of the falls, that’s the Vertical Head Height. It also has to force that water up to the falls through pipe and fittings that can be restrictive; that’s the Friction Head. The two components combined are the Total Dynamic Head, the total work the pump has to do to power any given water feature. Just like with cars, you want to match the motor to the work. If you’re just commuting to work every day at 30mph, you might not want to use a high performance muscle car that does 150 but gets 10mpg. On the other hand, if you need to go 150mph or move a ton of furniture or pull a heavy trailer, you’re going to need more muscle. The idea is to use (and pay for) only as much power as you need. The same goes for pumps. A low-head pump will cost far less to run than one capable of producing high head, so figuring out the Total Dynamic Head of your system so you know exactly what you need really pays off right from the beginning. One easy way to find the right flow at the right head for the lowest wattage is to use the Atlantic Water Gardens Let’s Talk Pumps Trifold. You put in the average width of the waterfall, the length of the stream if any and the desired visual effect you want to achieve and the worksheet will determine the appropriate pump capacity and tubing size, calculate your TDH and let you choose the right pump with the lowest wattage.

-

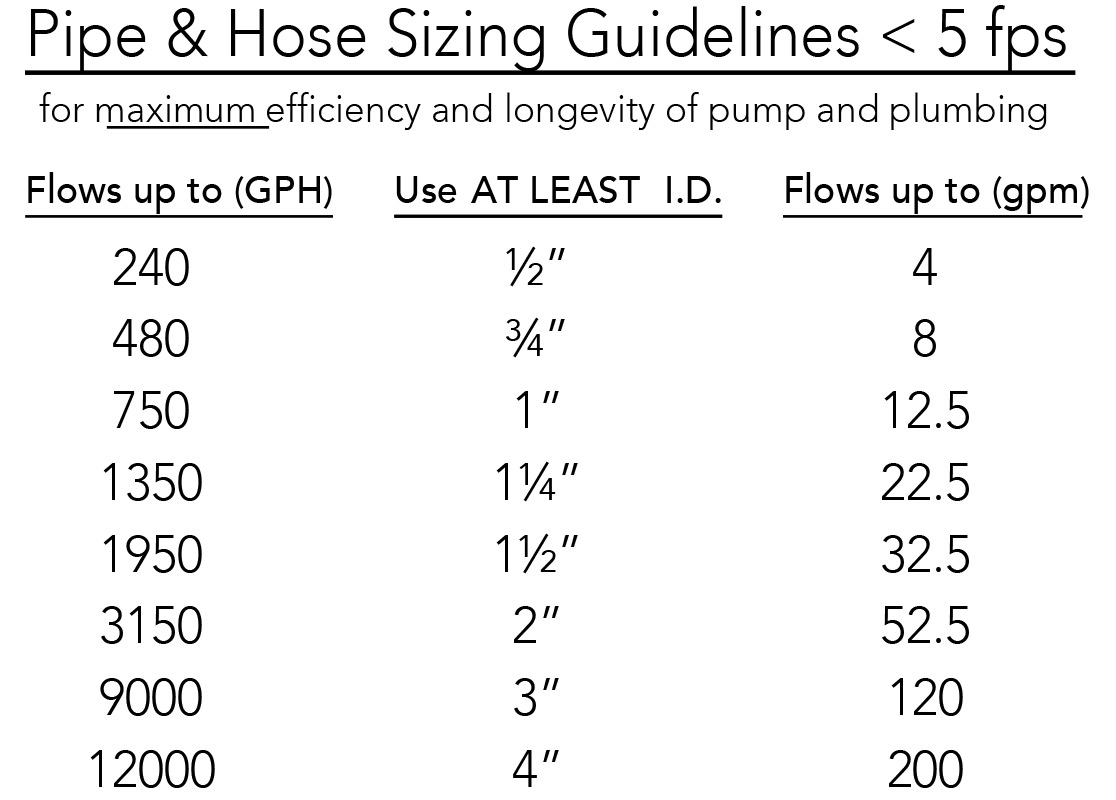

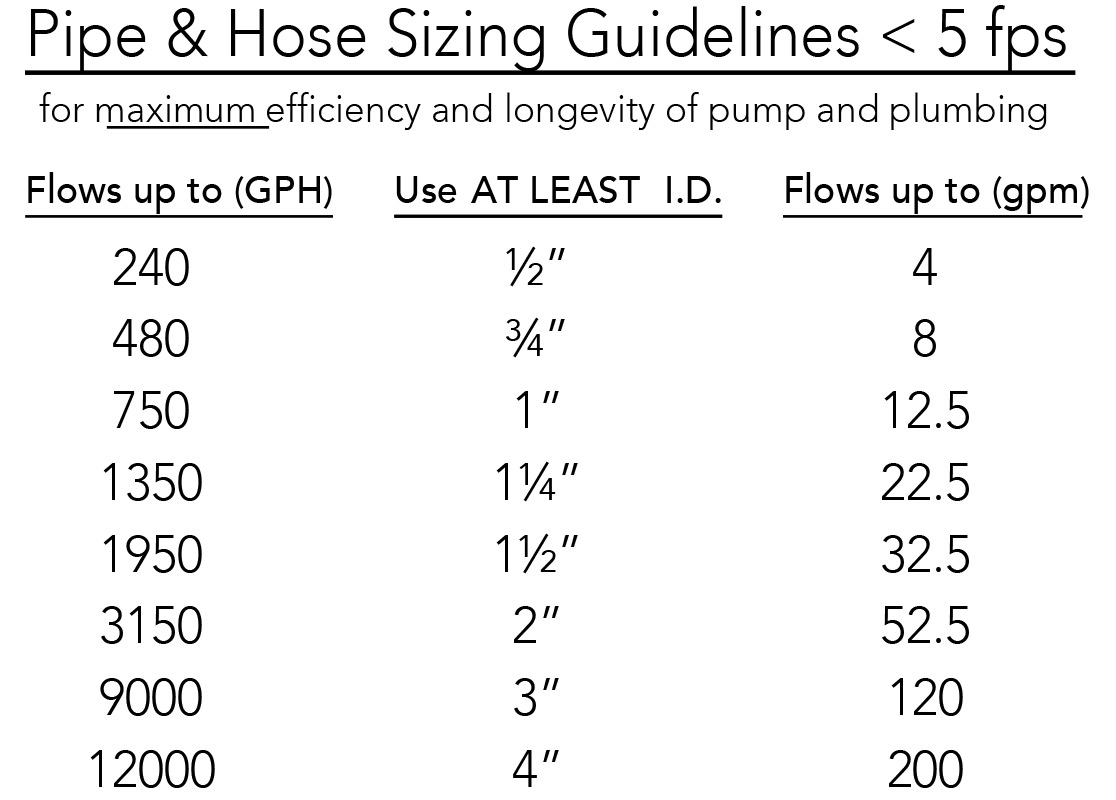

Use the right size tubing. The plumbing is just as important as the pump. Following the Pump Trifold recommendations to install generous, non-restrictive fittings and tubing will cut friction to a minimum and really save on operating costs. For example, utilizing 2” tubing for flows up to 3200 GPH and 3” from there up is recommended by most plastic fitting manufacturers, to reduce friction head and promote longevity of both pumps and plumbing. Savings of 25% over restrictive plumbing are typical.

Use the right size tubing. The plumbing is just as important as the pump. Following the Pump Trifold recommendations to install generous, non-restrictive fittings and tubing will cut friction to a minimum and really save on operating costs. For example, utilizing 2” tubing for flows up to 3200 GPH and 3” from there up is recommended by most plastic fitting manufacturers, to reduce friction head and promote longevity of both pumps and plumbing. Savings of 25% over restrictive plumbing are typical.

- Use a timer. Another way to moderate costs is with a timer. Unlike Ponds which are living systems that need constant circulation, Pond-free features can be turned off when there’s no one around to enjoy them. One popular option is to run the feature on weekdays only from the late afternoon until bedtime, say 5-11pm. Even with the waterfall running all weekend, that still saves 15/28ths, more than 50%, of the electric cost.

-

Use multiple smaller pumps instead of one large one. For larger features with flows over 10000 GPH, using multiple smaller pumps over single larger pumps of the same type will always save on electrical costs, because of the Laws of Affinity, which govern power consumption of centrifugal impellers. To oversimplify in a way that would drive my math teacher crazy, increasing the volume a pump produces requires squaring the power needed, and increasing the head height requires cubing the power! For our purposes, that’s as far as we have to go, thank goodness. It’s the corollary we can exploit to our advantage: cut the volume in half and you’ll always realize an exponential drop in power consumption, and you’ll really see savings when you cut the head height. That means that two half-size pumps will always cost less to run than one larger pump with double the capacity, all else being equal.

Use multiple smaller pumps instead of one large one. For larger features with flows over 10000 GPH, using multiple smaller pumps over single larger pumps of the same type will always save on electrical costs, because of the Laws of Affinity, which govern power consumption of centrifugal impellers. To oversimplify in a way that would drive my math teacher crazy, increasing the volume a pump produces requires squaring the power needed, and increasing the head height requires cubing the power! For our purposes, that’s as far as we have to go, thank goodness. It’s the corollary we can exploit to our advantage: cut the volume in half and you’ll always realize an exponential drop in power consumption, and you’ll really see savings when you cut the head height. That means that two half-size pumps will always cost less to run than one larger pump with double the capacity, all else being equal.

- Use the right type of pump for the job. Finally, the type of pump makes a huge difference. Tremendous advances in pump technology have been made over the last decade or two, with hybrid magnetic induction, variable speed control and axial flow designs that greatly reduce operating costs, but this isn’t the place to go into all that. To find the right pump, one that’s rated for continuous duty, that clogs infrequently and costs the least to operate, check out the AWGU College of Pumps. We’ll discuss the different kinds of pumps, how they function and where best to use each there.

This might not be the best place to discuss this, but if you’re thinking of building a Pond-free water feature, your pump and plumbing choices will make a big difference in your operating costs, which can mount up fast. For example, the monthly cost to run a pump is your average electric cost per kilowatt/hr times the pump wattage times 720 hours per month divided by 1000. Running 24/7, at $0.10/kW/hr, a 1000 Watt pump will cost $72 per month to run. (Check out the College of Pumps for a full explanation of pumps, plumbing and costs.) These tips will help you keep your water feature as affordable as possible.

-

Use the lowest head pump that will get the job done. Let’s take a quick look at the work your pump has to do. It has to raise water to the height of the top of the falls, that’s the Vertical Head Height. It also has to force that water up to the falls through pipe and fittings that can be restrictive; that’s the Friction Head. The two components combined are the Total Dynamic Head, the total work the pump has to do to power any given water feature. Just like with cars, you want to match the motor to the work. If you’re just commuting to work every day at 30mph, you might not want to use a high performance muscle car that does 150 but gets 10mpg. On the other hand, if you need to go 150mph or move a ton of furniture or pull a heavy trailer, you’re going to need more muscle. The idea is to use (and pay for) only as much power as you need. The same goes for pumps. A low-head pump will cost far less to run than one capable of producing high head, so figuring out the Total Dynamic Head of your system so you know exactly what you need really pays off right from the beginning. One easy way to find the right flow at the right head for the lowest wattage is to use the Atlantic Water Gardens Let’s Talk Pumps Trifold. You put in the average width of the waterfall, the length of the stream if any and the desired visual effect you want to achieve and the worksheet will determine the appropriate pump capacity and tubing size, calculate your TDH and let you choose the right pump with the lowest wattage.

-

Use the right size tubing. The plumbing is just as important as the pump. Following the Pump Trifold recommendations to install generous, non-restrictive fittings and tubing will cut friction to a minimum and really save on operating costs. For example, utilizing 2” tubing for flows up to 3200 GPH and 3” from there up is recommended by most plastic fitting manufacturers, to reduce friction head and promote longevity of both pumps and plumbing. Savings of 25% over restrictive plumbing are typical.

- Use a timer. Another way to moderate costs is with a timer. Unlike Ponds which are living systems that need constant circulation, Pond-free features can be turned off when there’s no one around to enjoy them. One popular option is to run the feature on weekdays only from the late afternoon until bedtime, say 5-11pm. Even with the waterfall running all weekend, that still saves 15/28ths, more than 50%, of the electric cost.

-

Use multiple smaller pumps instead of one large one. For larger features with flows over 10000 GPH, using multiple smaller pumps over single larger pumps of the same type will always save on electrical costs, because of the Laws of Affinity, which govern power consumption of centrifugal impellers. To oversimplify in a way that would drive my math teacher crazy, increasing the volume a pump produces requires squaring the power needed, and increasing the head height requires cubing the power! For our purposes, that’s as far as we have to go, thank goodness. It’s the corollary we can exploit to our advantage: cut the volume in half and you’ll always realize an exponential drop in power consumption, and you’ll really see savings when you cut the head height. That means that two half-size pumps will always cost less to run than one larger pump with double the capacity, all else being equal.

- Use the right type of pump for the job. Finally, the type of pump makes a huge difference. Tremendous advances in pump technology have been made over the last decade or two, with hybrid magnetic induction, variable speed control and axial flow designs that greatly reduce operating costs, but this isn’t the place to go into all that. To find the right pump, one that’s rated for continuous duty, that clogs infrequently and costs the least to operate, check out the AWGU College of Pumps. We’ll discuss the different kinds of pumps, how they function and where best to use each there.