The Third Annual Atlantic-OASE Professional Conference held last week in Cleveland Ohio was an event not to be missed. New this year, early arrivers attended 3 hands-on business workshops focusing on Business […]

Atlantic and OASE Expand Operations

Atlantic Water Gardens and OASE Living Water are pleased to announce an important milestone in the American water gardening market. Atlantic–OASE will be moving to a much larger location in […]

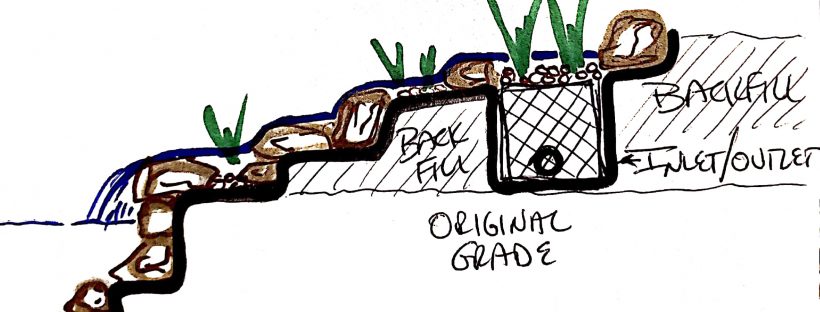

Bog Filtration Questions Answered

Duck Pond Bog Blog We recently received two questions on a previous blog: BOG FILTRATION, THE PERFECT COMPLEMENT TO BIOLOGICAL FILTERS. The questions had similar answers so we are sharing them […]

Tools That Don’t Suck – The Wobble Wedge

The Wobble Wedge – “a modular system of securely-stackable interlocking plastic shims”

Atlantic Professional Conference 2019

The season is upon us on Long Island. It’s getting warmer, the bulbs that we usually see in late March or April have actually bloomed – finally! Water temps are […]

Tools That Don’t Suck – Hypath Bags

Tools That Don’t Suck As water feature installers, my sons and I are used to hard, dirty, sometimes dangerous work. We enjoy what we do, whether it’s digging ponds, plumbing […]

Building and calculating an upflow bog with EcoBlox

We recently received a question on a previous blog: BOG FILTRATION, THE PERFECT COMPLEMENT TO BIOLOGICAL FILTERS. The question was: Do you have any additional information about building and calculating […]

Where in the World was Demi Fortuna?

“Where in the world is Demi Fortuna???” With these oft-repeated words the Chief, Jeff Weemhoff, begins the challenging and never-ending search for Fortuna’s whereabouts. Reports indicate that early on the […]

Atlantic Cord Seal Fitting

A great new way to hide power cords! Even the nicest water feature installation can be ruined if the cord for a pump or a light is visible, as they […]

The Atlantic Eco-Rise System

Bubbling Basalt Columns and overflowing vases set on buried Fountain Basins are attractive, easy and profitable add-ons for the irrigator, landscaper or hardscaper. These water features are especially popular with contractors who only occasionally […]