You asked so, here it is! A step-by-step guide to installing the Copper Bowls from the front of the 2020 catalog! What You’ll Need Re-Create It! Here are the steps […]

Atlantic-OASE Staff Picks: Three-Way Diverter

When our Social Media Director, Caitlyn, asked me to jot down something on a favorite product, I realized it might not be as simple a task as it sounds. There […]

Bog Filtration Questions Answered

Duck Pond Bog Blog We recently received two questions on a previous blog: BOG FILTRATION, THE PERFECT COMPLEMENT TO BIOLOGICAL FILTERS. The questions had similar answers so we are sharing them […]

Atlantic Cord Seal Fitting

A great new way to hide power cords! Even the nicest water feature installation can be ruined if the cord for a pump or a light is visible, as they […]

The Atlantic Eco-Rise System

Bubbling Basalt Columns and overflowing vases set on buried Fountain Basins are attractive, easy and profitable add-ons for the irrigator, landscaper or hardscaper. These water features are especially popular with contractors who only occasionally […]

Mining Completed Projects for New Business

One of the easiest ways to create new business is to prospect for new work in your existing customer base. For landscapers, hardscapers and poolscapers, getting a past customer to contract a […]

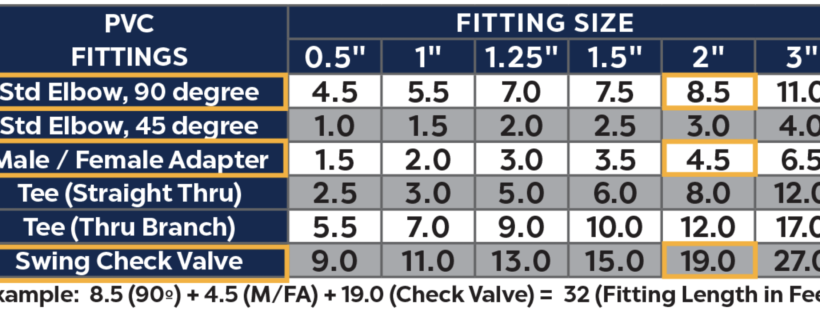

How to Calculate Total Dynamic Head

Finding the right pump for a water feature can be a challenge, and the stakes are high. The right pump, delivering the right flow at the right head height, while […]

Tools That Don’t Suck – Wiss W10TM Scissors

As water feature installers, my sons and I are used to hard, dirty, sometimes dangerous work. We enjoy what we do, whether it’s digging ponds, plumbing pumps, rolling boulders or […]

Tools That Don’t Suck – The Ryobi ES1500

As water feature installers, my sons and I are used to hard, dirty, sometimes dangerous work. We enjoy what we do, whether it’s digging ponds, plumbing pumps, rolling boulders or […]

Tools That Don’t Suck – Tirolessa Sprayer

As water feature installers, my sons and I are used to hard, dirty, sometimes dangerous work. We enjoy what we do, whether it’s digging ponds, plumbing pumps, rolling boulders or […]