200 Level 203 - Chapter 11

Protecting Asynchronous Hybrids

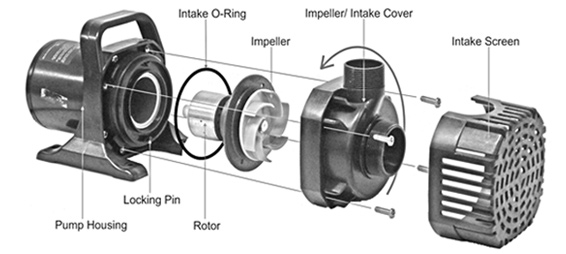

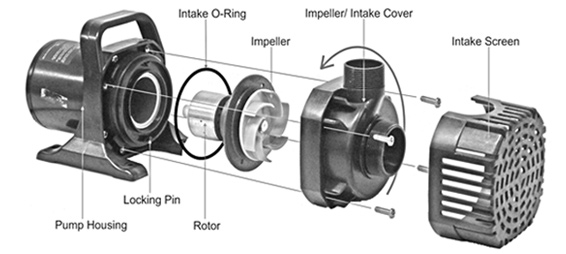

The popularity of these pumps is well-deserved. They are quiet, powerful and efficient, and can be long-lived if a couple of precautions are taken. Their efficiency is gained through tight tolerances between the spinning rotor and the ‘can’ it sits in. Any debris or deposits that build up in the space between them will eventually cause the pump to fail, either by wearing off the stainless steel cladding surrounding the copper coils, or by cementing the rotor into the can. Deposits around the rotor are the single greatest cause of Hybrid pump failure. Luckily, there is a simple, effective way to avoid an early demise.

Tip #4 – Open and inspect the pump after the first month of operation, especially in areas of hard water. If there is any evidence of hard water deposits, white vinegar should remove them with little effort. Check the pump again after another month to see if the pump will require monthly maintenance, or can go longer between cleanings. Although it does take some time and effort, regular cleaning will keep your Asynchronous Hybrid pump alive and well for years.

The popularity of these pumps is well-deserved. They are quiet, powerful and efficient, and can be long-lived if a couple of precautions are taken. Their efficiency is gained through tight tolerances between the spinning rotor and the ‘can’ it sits in. Any debris or deposits that build up in the space between them will eventually cause the pump to fail, either by wearing off the stainless steel cladding surrounding the copper coils, or by cementing the rotor into the can. Deposits around the rotor are the single greatest cause of Hybrid pump failure. Luckily, there is a simple, effective way to avoid an early demise.

Tip #4 – Open and inspect the pump after the first month of operation, especially in areas of hard water. If there is any evidence of hard water deposits, white vinegar should remove them with little effort. Check the pump again after another month to see if the pump will require monthly maintenance, or can go longer between cleanings. Although it does take some time and effort, regular cleaning will keep your Asynchronous Hybrid pump alive and well for years.